Designers love the time period sustainability as it’s their go-to once they can’t consider one other strategy to promote their designs!! (I’m positive each designer would relate)

On a extra critical word, they try to assemble a future alongside these traces as a result of everyone seems to be now conscious of its significance and it’s not a buzzword. Firms at the moment are taking steps to make sure that their operations are sustainable, and governments are introducing laws to encourage extra sustainable practices.

Designers have gotten extra conscious of the worth of a extra in-depth, process-oriented method. One such Korean designer noticed the staple use of tableware in individuals’s lives and created a 100% pure materials as an alternative choice to glass, ceramics, and different conventional uncooked supplies used to fabricate tableware.

Designer: SooA Choi

Ceramics are essentially the most used supplies for the manufacturing of tableware. These supplies are nice however contain quite a lot of unsustainable properties regarding manufacturing. The fabric is advanced to machine and might lose structural integrity if reduce incorrectly or with the flawed instruments. It requires excessive ranges of experience and results in the wastage of uncooked supplies. Machining ceramics and CMCs might be capital-intensive.

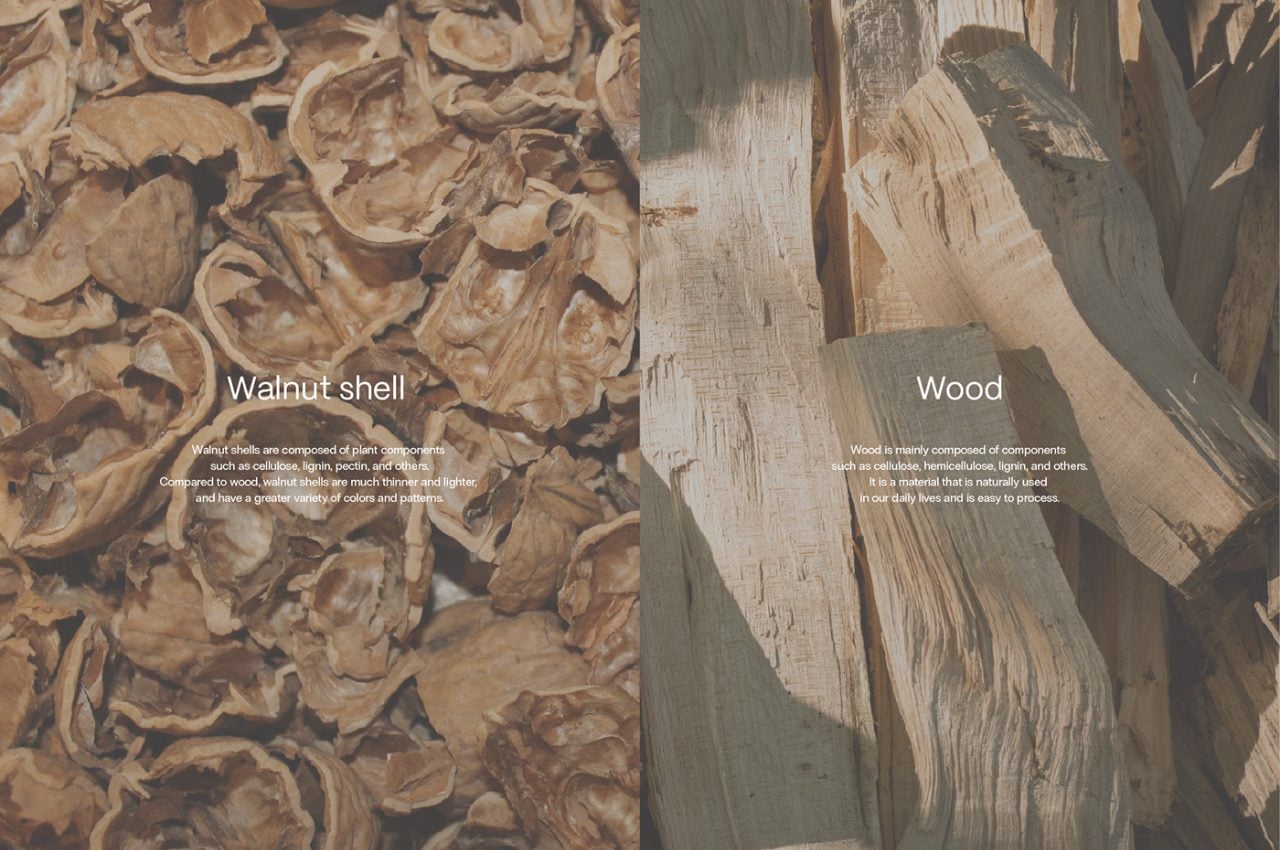

NOS is a mix of walnut shells, pine resin, and Canauva Powder. It presents new CMFs with various colours, patterns, and lightweight transmission because of grinding huge volumes of walnut shells into numerous sizes. The first binding agent is pine resin.

After being separated from the kernel, the shell of a walnut is taken into account waste and is discarded. The waste might be reworked into a whole plate from which to eat. Changing waste right into a useful resource is a vital facet of sustainability.

The qualities of a walnut shell and wooden overlap and can be utilized in on a regular basis conditions. Walnut shells are dry and onerous, which works to their profit because it stops bugs from coming into through holes and crevices, and it additionally makes them virtually odorless. Pine resin is tree sap that’s naturally antimicrobial and secure to eat in tiny doses. Nevertheless, the soldering of pine resin is hazardous to at least one’s well being and ought to be prevented in the course of the manufacturing of NOS. Walnut shells are extra sturdy than different pure supplies, which put on away with frequent use.

The manufacturing method for this materials is kind of easy and extremely sustainable; no synthetic components are used. It solely wants the suitable ratio of binders, a mould, and floor walnut shells. To supply the required form, the substance is poured into the mould. Within the occasion of undesirable outcomes in the course of the NOS manufacturing course of, the earlier procedures might be repeated and no product is wasted. The finished type faraway from the mould is fired at a excessive temperature of over 400 levels to use the glaze. Carnauba wax is poured onto it to extend sturdiness and forestall scratches.

NOS is a flexible materials utilized in numerous kinds and sizes. As urged it’s used for tableware like small and huge plates, glasses, vases, and many others. It will also be used for different decors round the home because the aesthetic worth of the completed piece enhances a zen inside design.